Customer services

Bringing many years of engineering and technical experience to customers' operations through our growing range of service

Air Liquide Engineering & Construction have been supporting the Air Liquide Group over the long term with services to maintain the Group’s assets. Today, the Air Liquide Group is present in 75 countries across the world with a large number of production facilities to service its customers.

Drawing on this track record of operational excellence, Air Liquide Engineering & Construction brings its many years of engineering and technical experience to customers' operations by providing a growing range of services to maximize the efficiency and reliability of our customers’ assets.

Customers can enjoy the reassurance of working with a single reliable partner and clear visibility over operating costs and fully optimize each process in the short and longer term

Our expertise

Our approach

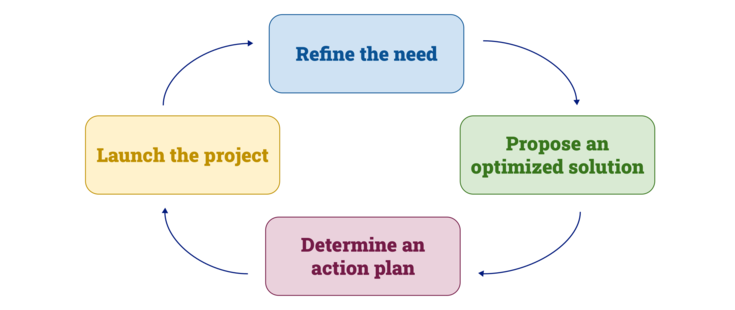

- Refine the need: after receiving an enquiry, a Services Manager will investigate the best solution

- Propose an optimized solution: a technical proposal is created and expert advice provided

- Determine the action plan: once a customer accepts a proposal, resources are booked and a schedule confirmed

- Launch the project: a dedicated team are involved from start to finish of the project

Our portfolio

Engineering Services

Support for designing front-end developments and all types of pre-engineering for production projectsWith our multi-skilled team of engineers, we can respond to requests for pre-studies for ambitious new projects and carry out development studies that can modernize plants already in operation. We not only have mastery of standard plant activities, but can also support customers’ needs for innovation – deploying technologies such as carbon capture, low carbon hydrogen or electrolysis.

Our engineers seek to deliver maximum efficiency at the best available cost, always making sure that protecting the health, safety and the environment is of priority.

Our Engineering Services include:

- Design or Innovation Support

- Feasibility study

- Modification/Conversion/upgrade

- Optimization study

- Debottlenecking

- Plant life assessment/extension

- FEED (Front End Engineering Design)

- Detail Engineering

- Small project Engineering & Procurement

- Revamping & Plant Reallocation

In practice

A customer in Iberica faced difficulties with the main heat exchanger in the Air Separation Unit. Air Liquide Engineering & Construction dispatched a specialist to the site to assess damages, carry out a root cause analysis, and help with initial troubleshooting and repairs. The customer subsequently decided to secure production by ordering a new main heat exchanger. Our experts completed the engineering and integration studies for a new design and supported the procurement and installation of the new heat exchanger. The replacement was successfully completed by a team of process, process control and site engineers during a major shut down. The plant successfully restarted at full capacity after a short period of downgraded production.

Remote Support Services

Providing tailored operational solutions that address a unit’s operational challengesAir Liquide Engineering & Construction have a high level of experience in remote services and are able to mobilize skilled experts to diagnose and solve problems or provide training from our offices, wherever the customer is located.

We understand the financial challenges and tight deadlines that are often imposed on operational sites, and have the ability to provide the right technologies and solutions to any location that best suit the customers’ circumstances.

Our remote support services include:

- Procurement Services (inspection and expediting)

- Start-up assistance

- Diagnosis

- Accident risk analysis

- Root causes analysis

- Operation support

- Maintenance support

- Troubleshooting

- FEP optimization

- Vulnerability study

- HSE study

- Functional analysis & logic updating -

- e-Learning

- Plant Simulator

- Construction support (Method of statement preparation)

In practice

During Covid 19 restrictions, a customer operating at a remote site in Australia contacted us requesting specialist support for the re-start of an Air Separation Unit following a major turnaround on site. As a result of the pandemic restrictions, it was impossible for Air Liquide engineers to visit the customer’s location. We therefore provided round the clock support on a remote basis, drawing on the availability of our engineers located around the world. In doing so, we helped the customer to restart the Air Separation Unit without problems and on time.

On-Site Services

Deploying the best technical expertise to support any type of complex actions on unitsRunning an Air Separation Unit on a daily basis requires a high degree of operator know-how and skill. Even the latest, most automated Air Separation Units require considerable operator experience and insight to address the challenge of operating and sustaining performance at the rate of efficiency required.

At Air Liquide Engineering & Construction, we design and operate Air Separation Units all over the world, at a level of efficiency over 99%. Customers often ask us to share our expertise on their sites; not only during commissioning or shutdown, but in everyday and continuous improvement operations.

We can offer a one-stop shop service: to check a plant’s performance, carry out a plant assessment, help to install new equipment and components, troubleshoot and problem-solve, and help our customers to find the most safe, reliable and efficient solutions.

Our on-site services include:

- Audit

- Inspection

- Ultrasonic Leak detection

- Assistance for start up

- Expert support

- Flash diagnosis

- Supervision of installation

- Supervision of supplier intervention

- Troubleshooting

- Operation Support upon emergency call

- Analytical deriming

- Training

In practice

A customer in Indonesia began to encounter difficulties with the operation of their Air Separation Unit, which had been active for some 30 years. One of the difficulties was the percentage of oxygen increasing rapidly within the perlite areas of the Cold Box. Our emergency experts were activated to provide daily monitoring and support. An Air Liquide oxygen expert visited the site to carry out a detailed assessment. A root cause analysis indicated the strong probability of a leak inside the Cold Box. Working with the customer, the team planned a shutdown of the Air Separation Unit and sent site engineers equipped with leak detectors suitable for the research required.

Their analysis found leaks in the Cold Box, including one on a small pipe which was the principal cause of the increased percentage of oxygen. We supported the customer during repairs and testing, and the Air Separation Unit was brought back on stream smoothly, returning to its initial production capacity thanks to the proactive teamwork and permanent monitoring.

Procurement Services

Providing advice and supplying equipment at the most competitive price to support maintenance needsAir Liquide understands the importance of on-site availability of the right spare parts, for routine of planned operations or when responding to an unplanned event or emergency.

As a global company, our extensive procurement network allows us to manage delivery and logistics anywhere and on time, at the best competitive price. With our safe and reliable strategic sourcing, we can be your complete spare parts solution, from initial specification through to installation and maintenance.

Long Term Service Agreements

Specifically tailored long term service agreements adapted to customer’s needsOur experience over many years servicing our customers has led us to see the mutual benefit in establishing Long Term Service Agreements.

By building and reinforcing long-term relationships based on trust, a Long term service agreement provides customers with a tailored services package and access to Air Liquide’s knowledge and experience through a dedicated single point of contact.